Controlling Water and Chemical Usage for a Cleaner Vehicle Wash

It may be patently obvious, but it’s worth bearing in mind – water is the lifeblood of the vehicle-wash industry. Without its ready availability, professional washes would cease to function. That’s why savvy wash operators know that they must treat their most precious resource with as much tender loving care as a conscientious car owner lavishes on a vehicle.

But it hasn’t always been that way. In years past, water was treated as nothing more than an easy-to-acquire commodity that simply helped keep the wash running. That attitude has undergone a steady evolution, driven by rising costs for water and sewer service nationally, as well as an overall “greener” attitude among consumers, one that is demanding increased environmental responsibility from the companies that they do business with.

The International Carwash Association is helping vehicle-wash operators in this area through its WaterSavers® water-treatment and conservation program, which has been designed to help professional wash operators promote the environmental responsibility of their “green” business practices. Specifically, wash operators are being asked to search out systems that route used wash water and chemicals to water-treatment facilities, along with those that require as little as 40 gallons (151.1 liters) of freshwater per wash cycle, which is less than a standard vehicle wash machine.

Used wash water and residual chemicals have the potential to impact the environment, and this risk is something to be taken seriously. Reduction in the volume of water and chemicals used in each wash, thus reducing the amount of used water that needs to be treated, is one of the best ways that vehicle wash equipment can combat the risk of environmental contamination.

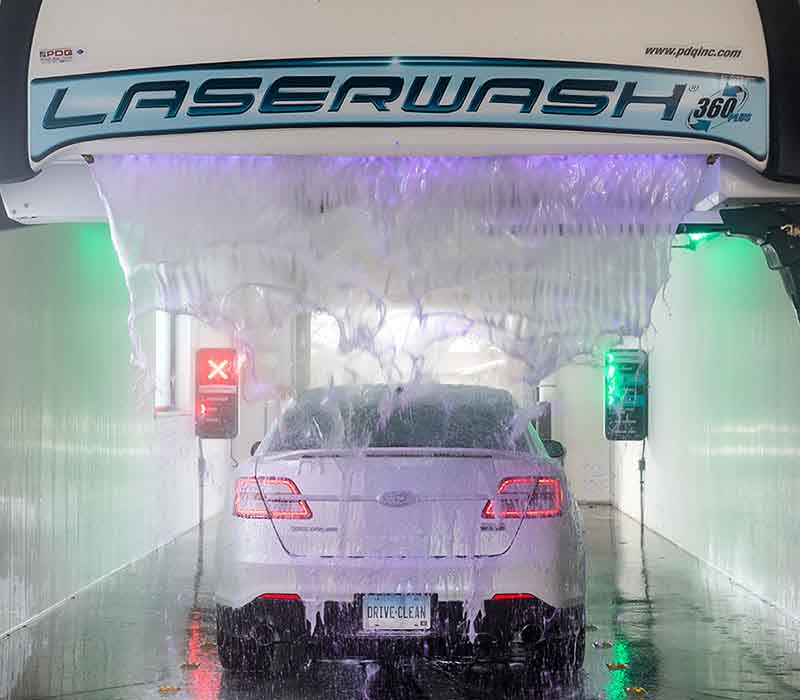

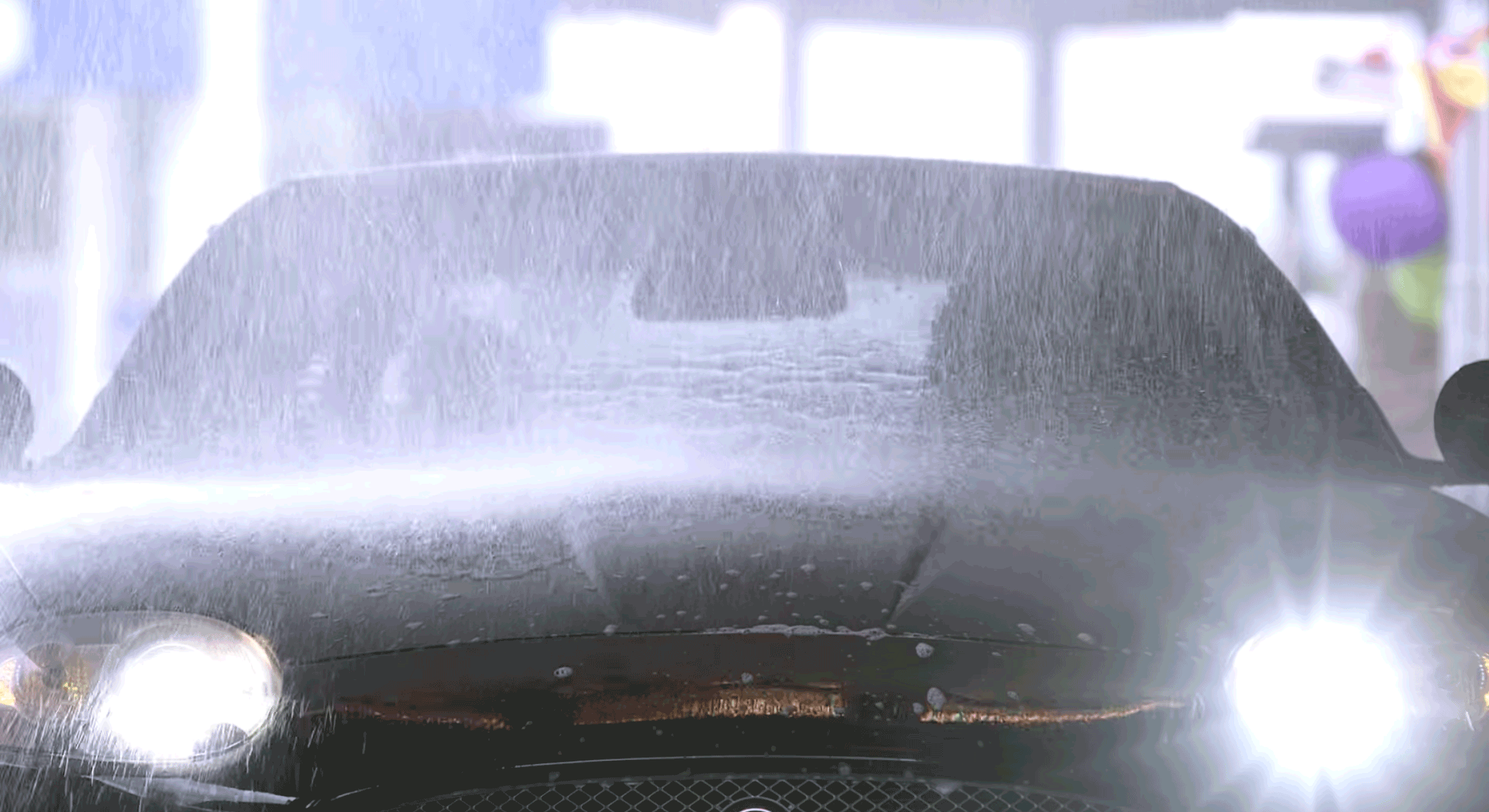

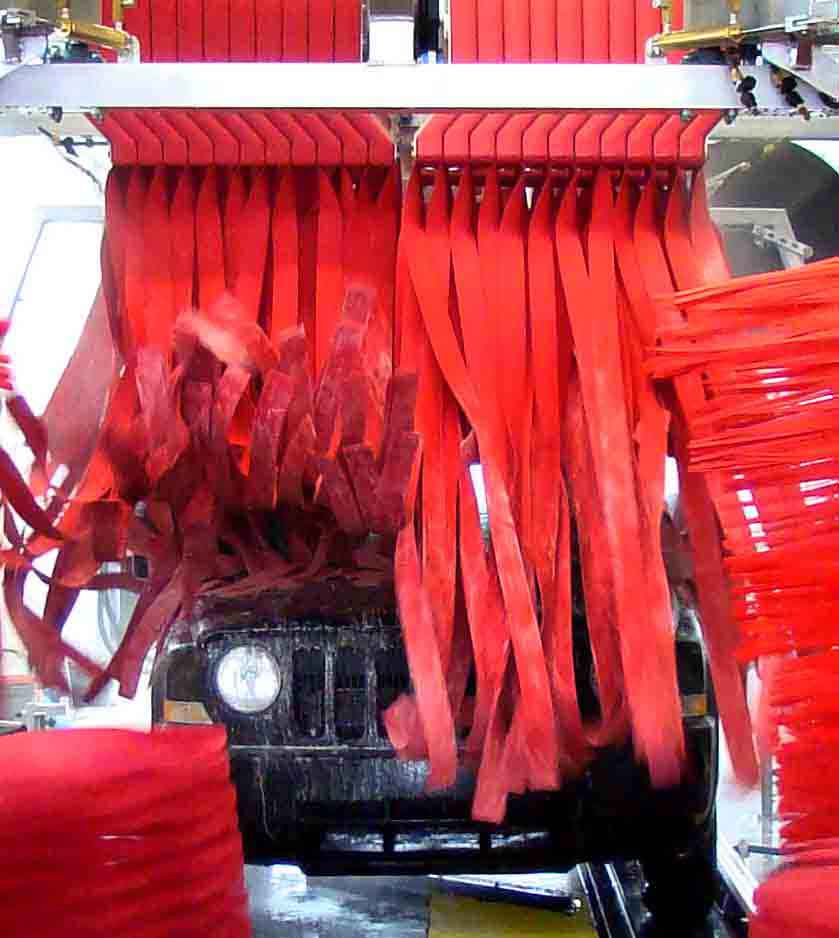

Thankfully, the companies of OPW Vehicle Wash Solutions – PDQ Manufacturing, Inc., and Belanger, Inc. – have a long history of working tirelessly to create systems that meet the strict tenets of socially responsible operations. Both companies are more committed than ever to creating wash systems that are designed to protect the long-term well-being of the environment through responsible water and chemical usage and proper routing of wastewater. In addition to being socially responsible, PDQ and Belanger wash systems – which include industry-leading in-bay automatic, conveyorized tunnel and hybrid friction/soft-touch systems – leave a smaller environmental footprint while simultaneously reducing operational costs and maximizing profitability.

OPW’s commitment to creating the most environmentally sensitive vehicle-wash systems grows from its Defining What’s Next philosophy of ensuring strong Environmental & Social Governance (ESG) operating principles. The pillars of this philosophy are Protecting People, Protecting the Environment and Enhancing Business Performance, all of which are addressed through the vehicle-wash systems and components produced by PDQ and Belanger.

/Industry%20Fleet%202.jpg.fullsize.1280.1280.png)